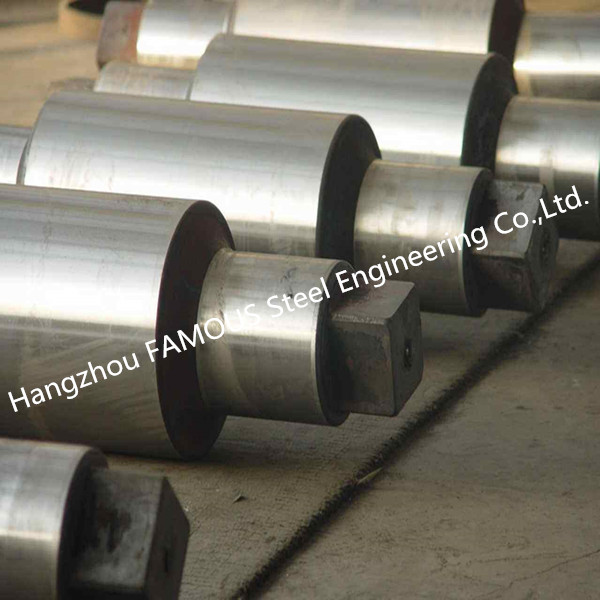

Centrifugal Casting Heat Resistant Furnace Steel Hot Strip Mill Rolls Dust Proof

Centrifugal Casting Heat Resistant Furnace Steel Hot Strip Mill Rolls Dust Proof

We supply a widest range of Hot Strip Mill Rolls used for Rolling Mill of different dimensions and strength as per the custom requirement of the client. some more specification of the rolling mill work rolls are 2 Hi Mill work Roll, 4 Hi Mill work Roll , 6 Hi Mill work Roll , 2nd Intermediate roll ,20 Hi Mill Roll ,20 Hi Work Roll.

The Work rolls are manufactured of particularly high-quality alloyed steels. They are distinguished by high hardness for the depth up to 45 mm that ensures an improved durability under severe conditions of high-speed rolling which is accompanied by heat shocks in operation.

Guaranteed features of forged steel work rolls for cold rolling

High and uniform hardness after hardening (within 1-2 HSD over the barrel)

Effective layer depth over the radius (20-40 mm)

High thermal fatigue resistance during overall and local heat-up, increased heat resistance (high hardness is maintained for a long time under steady-state thermal conditions of the roll);

Resistance to surface defects, cracking, lamination, scabbing, spalling, tearing, etc.

High surface quality after heat treatment and machining

Favourable distribution and minimal value of residual stresses after hardening and machining

Absence of metallurgical defects and impurities

Absence of flakes, coarse carbide clusters, carbide network, large-pattern acicular martensite and other macro- and microstructural defects

Absence of machining defects

Specification

| Item | MC3 forged work roller steel rolling mill |

| Handcrafte | furnace rolls are comprised of statically cast trunions (ends) welded to a centrifugally cast roll body with our unique locking mechanism. |

| Temperture | can perform in high temperture |

| Advantage | Our dry rolls are comprised of statically cast trunions (ends) welded to a centrifugally cast roll body used in a tunnel furnace |

| our dry rolls will provide abundant fuel savings through reduced heat loss in the furnace |

Advantages:

More than 30 years of professional experience and continuous R&D efforts enable us to offer better custom design and engineering advice.

Use only new raw material like nickel plate, chrome iron, cobalt, ferrotungsten to guarantee physical property and increased service life of our castings.

Owned in-house production and inspect facility to guarantee the best quality.

Experienced workers for foundry, machining and welding guarantee excellent quality and prompt delivery

DESCIPTION of Work Rolls or Backup Roller:

1) Material: Alloy Steel, Alloy Iron, Ductile Iron namely 9Cr3Mo, 70NiMoV etc.

2) Standard: GB, AISI, SAE, ASTM/ASME, EU, AS/NZS etc

3) Size: According to clients’ drawing or design needs

4) Hardness: based on design specification

5) Chemical Composition and mechanical property: as specified.

Packing and preservation

Packing and preservation methods depend on the contract conditions and on the climatic zone where the rolls are going to be supplied, as well as on the transportation and storage conditions.

The items ready to be shipped are covered with a preservative coating – several layers of primer and enamel.

The roll necks are wrapped into anticorrosive paper with polyethylene coating and into waterproof paper.

Storage and service

The rolls should be stored at a non-heated storage, on special shelves, resting on their necks.

Ageing or periodical low tempering is strongly recommended during roll operation life.

Our special steel company can do various customized work rolls machining and fabrication ranging in different sizes and processes as per client’s drawing shown or the requirements. please feel free to make any enquiries accordingly.