Metal Fabrication

Famoussteel's metal fabrication services are second to none. We use the latest technology and equipment to create custom metal products that meet your exact specifications. From design to delivery, our team of experts will work with you every step of the way to ensure your project is a success. Whether you need a single prototype or a large production of prefab steel structures buildings, we have the experience and expertise to get the job done right. Our commitment to quality and customer satisfaction is unmatched, and we pride ourselves on delivering projects on time and within budget.Contact us today to learn more about our metal fabrication services and how we can help bring your project to life.

-

America Standard AWS D1.1D1.5 Fabricated Steel ...

-

Skewed Curved Steel I-Girder Truss Bridge Const...

-

UK British Standard Preassemble Steel Pedestria...

-

Municipal Use Steel Framing Street Light Poles ...

-

Galvanized light steel frames prefab villa hous...

-

Steel Traffic Signals Traffic Light Pole

-

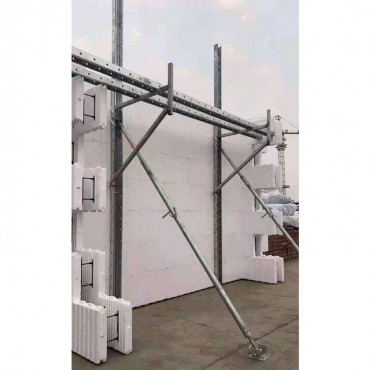

Insulated Concrete Forms EPS BuildBlocks ICF wa...

-

Prefabricated Galvanized 30-50mm Diameter Steel...

-

Truss Structural Steel Bridge Fabrication AASHT...

-

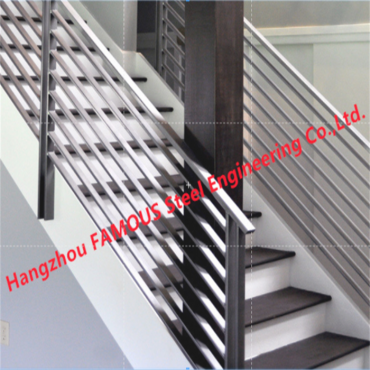

Customized Aluminum Balustrade Stair Handrail f...

-

Round or Rectangle Top Pipe Smooth Anticorrosiv...

-

America Standard AWS D1.1D1.5 Fabricated Steel ...