Metal Fabrication

Famoussteel's metal fabrication services are second to none. We use the latest technology and equipment to create custom metal products that meet your exact specifications. From design to delivery, our team of experts will work with you every step of the way to ensure your project is a success. Whether you need a single prototype or a large production of prefab steel structures buildings, we have the experience and expertise to get the job done right. Our commitment to quality and customer satisfaction is unmatched, and we pride ourselves on delivering projects on time and within budget.Contact us today to learn more about our metal fabrication services and how we can help bring your project to life.

-

Australia Standard Steel Structure Commercial a...

-

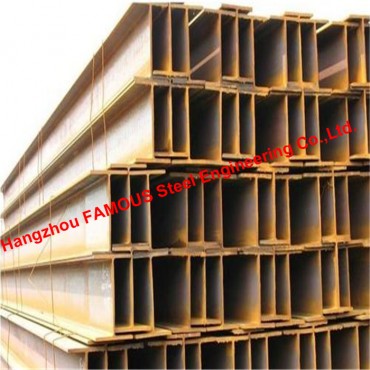

UK US Standard Hot Rolled H Beam Steel In Narro...

-

Australian Standard For Steel Structure Scaffol...

-

Pure Europe Standard Hot Rolled H Beam Steel In...

-

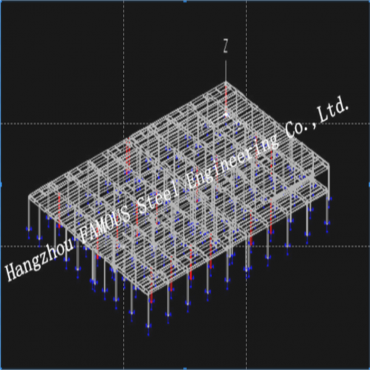

Urban Planning And Structural Steel Building Co...

-

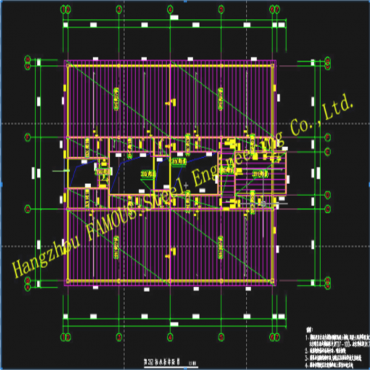

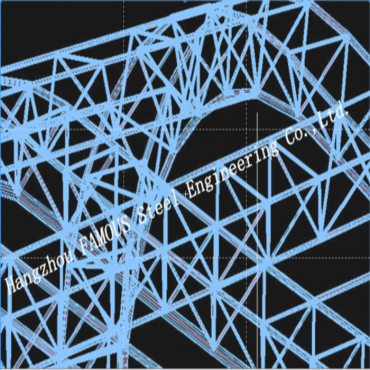

Pipe Truss Planning Structural Engineering Desi...

-

Synthetic Stadium Steel Structure Building Arch...

-

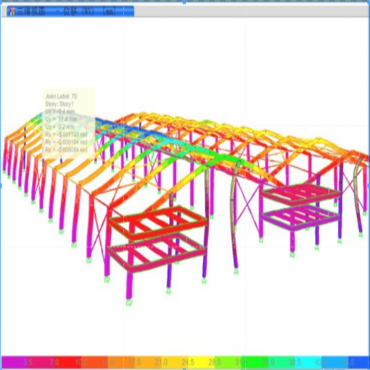

3D Location Structural Engineering Designs With...

-

New Zealand AS/NZS Standard Structural Steelwor...

-

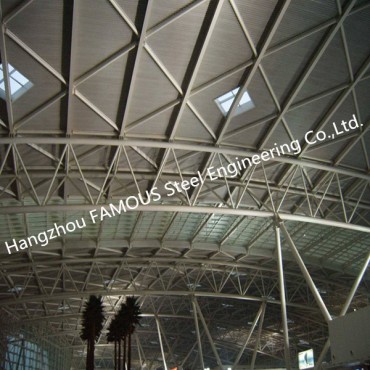

Customized Steel Pipe Structure Space Framing R...

-

Prefabricated Steel Membrane Structure Space Fr...

-

Stainless Steel High Precision Forged Steel Bac...