Modern Design Layout Optimization Power Plant Steel Structures with Surrounding Systems

Modern Design Layout Optimization Power Plant Steel Structures with Surrounding Systems

We are:

China’s Top Grade Fabricator for Steel Structure Manufacturing

A-level for Professional Project Design of Prefab Steel Structures

National Grade Ⅰ Specialty Contractor for Steel Structures

TECHNICAL PARAMETERS

Except normal structures fabrication, we can also do nonstandard prefab steel structures fabrication according to client’s sample or drawings like for power plant equipment, cement production line, petrochemical line, industrial equipment etc:

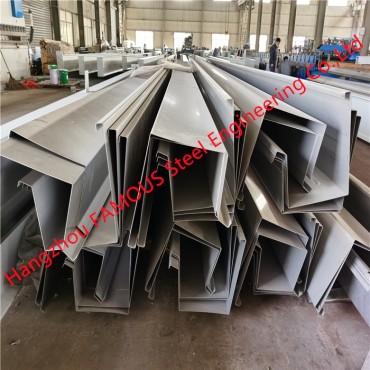

Special shape structures(super-wide steel plate, etc for mining or power supply field.);

Industrial steel frames(cement framing, belt conveyor and other supporting frames, etc.);

Platforms(sea drilling platform, viewing platform, etc.);

Car racks;

Steel gallery;

Steel tower;

Steel working tables for workshop;

Chutes;

Reclaimer and decker parts etc.

Elevator shaft steel structure;

Steel staircase;

ETC…

PRODUCT SHOW

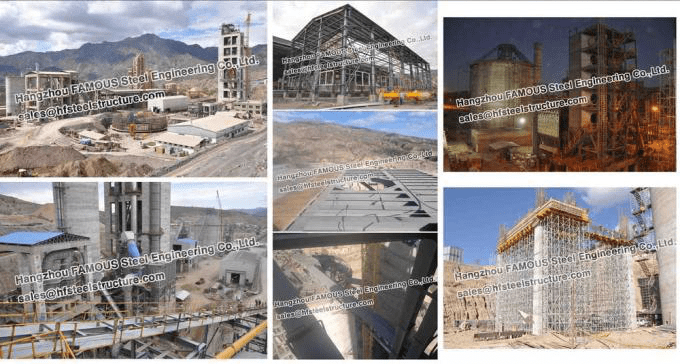

Bolivia Cement Plant

Supporting frames, belt conveyor, workshops, steel staircase, etc.

Steel consumption: 3,655.72 tons in the first phase, 7,200 tons in the second phase

In this project, also includes some special-shaped members fabrication:

| Item Name | Structural steel member fabrication – power plant steel structures |

| Main Steel | Steel structure–Q345/Q235, special high tension plate, etc. can be customized according to customer’s requirements. |

| Surface | Painted or Hot Dip Galvanized, or according to customer’s requirements. |

| Connection method | welding connection or bolt connection, etc. |

| Column and Beam | Welded H section, Hot Rolled Section Steel, grid column, pipe&tube column,etc. |

| Service | Design, Detailing, Fabrication and Installation (Standard: America Standard, Australia Standard, England Standard, China Standard, etc. Design and Detailing software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, 3D3S, Tarch, Tekla Structures(Xsteel), etc.We also can process/fabricate according to client’s sample or drawings.) |

| Making quotation according to customer’s drawing or as per customer’s dimension and requirement; Offering a free preliminary design drawing(formal complete design need to be paid [high-quality, low-cost] ). |

|

| Packing | We possess the unique most professional and best packaging in China presently – framing package, which perfectly protects the structural steel members from any impact damage during the transport. Or according to customer’s requirement. |

| Load into 40/20GP, 40HQ, 40OT or Bulk carrier |

PRODUCTION LINES

Our group introduced from abroad the world-class professional production lines of steel structure, has the most advanced automatic H-beam production lines, pipe truss, box beam production lines, CNC hydraulic punching after-cutting C and Z types steel production lines, wall & roof panels, metal sandwich panel production line, etc., can complete all kinds of light steel, heavy steel, high-rise multi-spatial structure steel products processing tasks with high quality and efficiently.

BOXBEAM PRODUCTION LINE

Box Assembling Machine Intersection Line Cutter Molding Machine

Dual-arc Double Wire Welder Electroslag Welder Face Miller

PIPING TRUSS INTERSECTING PRODUCTION LINE

H-BEAM STEEL PRODUCTION LINE

Tridimensional Drill Machine CNC Sawing Machine CNC Spot Facer

TECHNOLOGY R&D

Our group has over 1,500 employees of whom 206 are engineering technicians of all levels and all kinds and over 60 are state GradeⅠ, Grade Ⅱ registered structure engineers, builders and architects.

The company has senior colleges and professional technology design organizations as the technology backup force and has established wide cooperation and R&D relations with such technology research institutes as Zhejiang University, Northwestern Polytechnical University, Zhejiang Shuren University, etc.

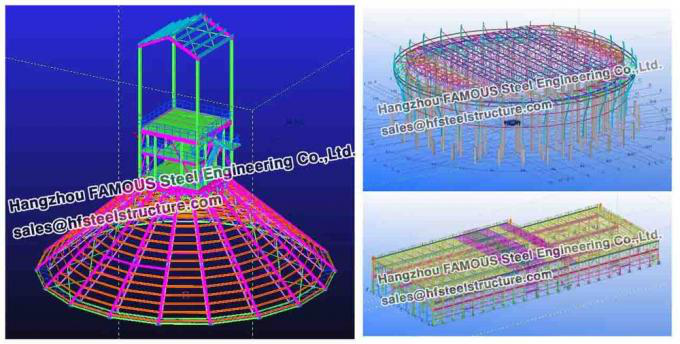

DESIGN AND DETAILING

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Etabs, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures(Xsteel), 3D3S, Tarch, etc.

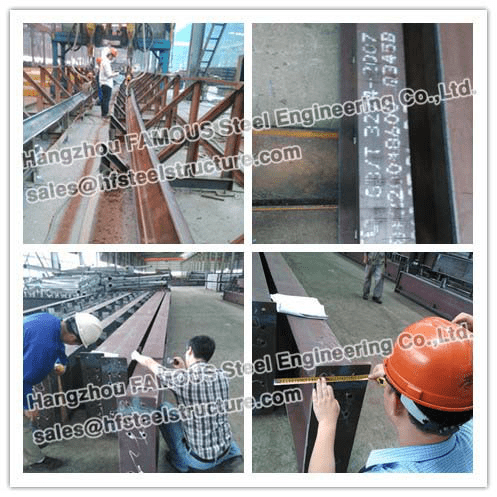

QUALITY INSPECTION BY BV, SGS, SKM, ETC.

Systematic Quality Process and Progress Control documentation: our fabrication process has been controlled by series of documentation and quality testing which are monitored and certificated by BV, SGS, SKM, JACOBES etc world-famous third party inspection organization.

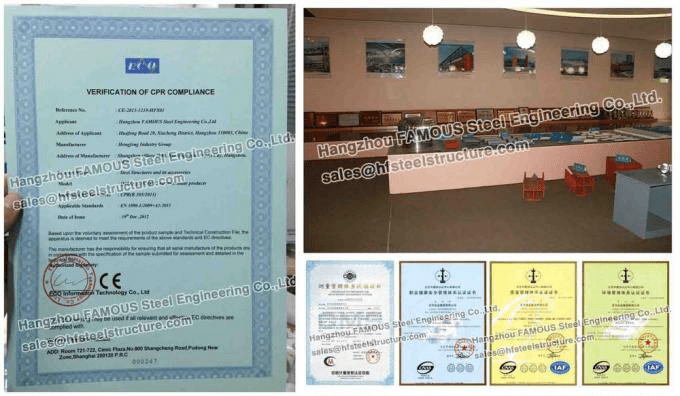

CERTIFICATIONS

We have CE Certificate, AWS Certificate, ISO9001 Quality Control Certificate, ISO14001 Environment-friendly Certificate etc systematic certificates to ensure our whole production progress controllable.

We also have systematic Quality Process and Progress Control documentation: Our fabrication process have been controlled by series of documentation and quality testing which are monitored and certificated by BV, SGS, SKM, JACOBES etc world-famous third party inspection organization.

SOME OF OUR INDUSTRIAL STRUCTURAL STEEL FABRICATION PROJECTS

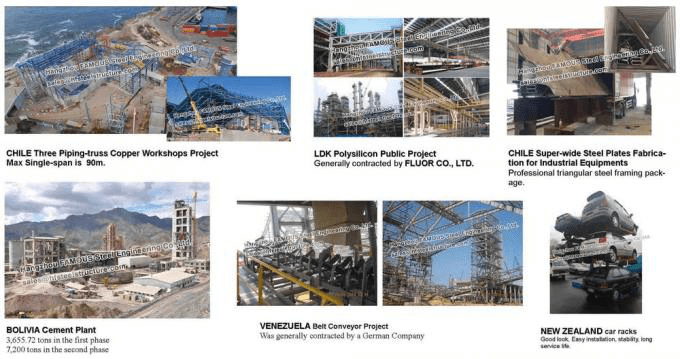

CHILE Three Piping-truss Copper Workshops Project:

Max Single-span is 90m.

LDK Polysilicon Public Project:

Was generally contracted by FLUOR CO., LTD., the total steel consumption volume for Phase I project reached over 30,000 tons and this program was in a high-rise steel structure of 4-7 floors.

CHILE Super-wide Steel Plates Fabrication for Industrial Equipments:

Professional triangular steel framing package.

VENEZUELA Belt Conveyor Project:

Was generally contracted by a German Company.

BOLIVIA Cement Plant:

Steel consumption: 3,655.72 tons in the first phase, 7,200 tons in the second phase.

NEW ZEALAND car racks:

Good look, Easy installation, stability, long service life.

CUSTOMERS’ VISITS

Welcome your visit!

IF YOU NEED A QUOTATION, PLEASEPROVIDE US WITH THE FOLLOWING BASIC INFORMATIONS:

1. Send us your sample or drawings.

2. If you don’t have, we can design for you.

OTHER PRODUCTS MIGHT YOU NEED

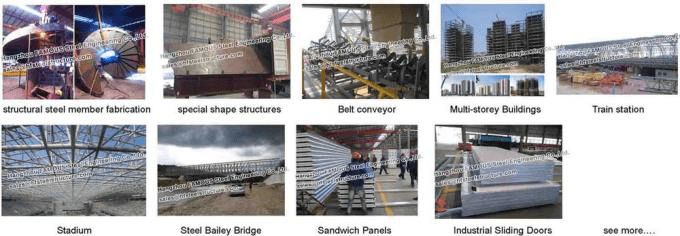

structural steel member fabrication special shape structures structural steel workshops Belt conveyor Multi-storey Buildings

Stadium Steel Bailey Bridge Sandwich panels Industrial sliding doors Train station see more….