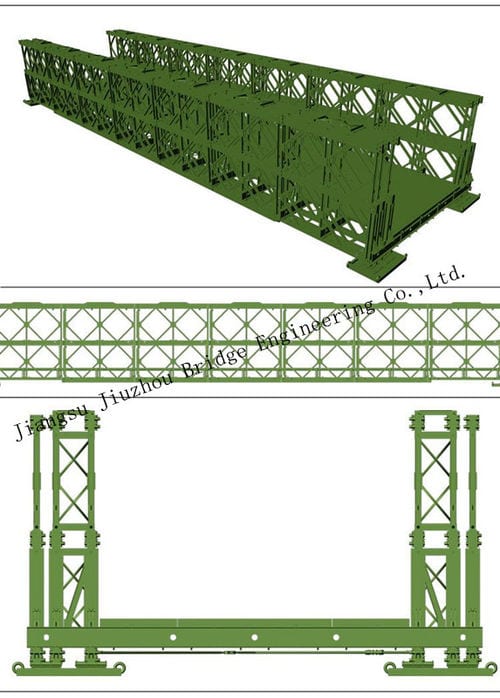

1. 321 type steel bridge Bailey net lane width is 3.7 meters; 200 steel bridge net lane width has two kinds: standard width is 4.2 meters (convenient for special vehicles);

2. The staggered arrangement of the joint between the chord and the truss is strengthened to reduce the inelastic deformation caused by the pin hole clearance, and the pre-arching method is adopted to greatly reduce the vertical deflection of the bridge span. The 321 type steel bridge cannot be arranged in this way, and the deflection of the whole bridge is larger than that of the HD200 steel bridge.

3. The bolt connection member adopts the method of positioning and fixing of the guide sleeve to increase the connection precision of the product, the guide sleeve is sheared, the bolt is pulled, the service life of the bolt is improved, and the safety of the steel bridge is ensured.

4. HD200 wind-resistant rod is made into a single type, and connected with the beam to improve the overall stability of the steel bridge.

5. The horizontal support frame of the HD200 steel bridge is fixed between the horizontal support frame and the truss piece. This ensures that the whole bridge has no side bends and the whole bridge is well equipped with pre-camber.

6. Steel bridge components are less convenient for assembly, disassembly, transportation and storage.

7. In the case of large span, the 321 type steel bridge obviously exceeds the HD200 steel bridge in the amount of steel used. The 321 type steel bridge combination form is: three rows of single-layer reinforced type, and its weight is: 57.2 tons. The HD200 steel bridge combination form is: double-row single-layer reinforced type, its weight is: 54.8 tons, which saves 2.4 tons of steel than the 321 type steel bridge, and its steel bridge Bailei sales net lane also increases to 4.2 meters, which is convenient for vehicles. by.

8. When the special load is required, the 321 type cannot bear, and the HD200 steel bridge can pass the maximum load of 60 tons

Post time: May-07-2019