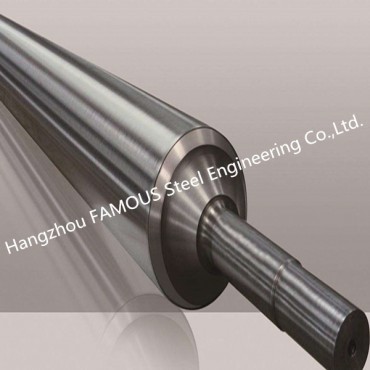

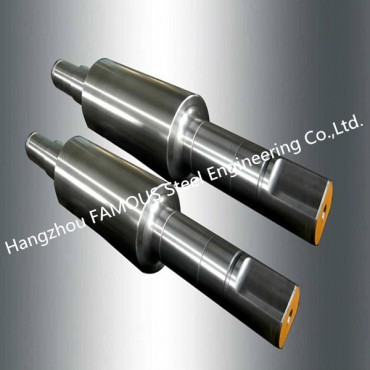

Kub Strip Mill Rolls

Stainless hlauKub Strip Mill Rollsrau ua kom tiav cov ntu hnyav chilled yob thiab rov qab rau cov menyuam refurbishment

Peb muab ib tug widest ntau yam ntawmKub Strip Mill Rollssiv rau Rolling Mill ntawm qhov sib txawv thiab lub zog raws li kev cai ntawm tus neeg siv khoom.Qee qhov tshwj xeeb ntxiv ntawm cov dov zeb ua haujlwm yob yog 2 Hi Mill ua haujlwm Yob, 4 Hi Mill ua haujlwm Yob, 6 Hi Mill ua haujlwm Yob, 2nd Intermediate yob, 20 Hi Mill Roll, 20 Hi Ua Haujlwm Yob.

Cov rolls ua hauj lwm yog tsim los ntawm tshwj xeeb zoo alloyed steels.Lawv txawv los ntawm qhov siab hardness rau qhov tob txog li 45 hli uas ua kom muaj kev txhim kho ruaj khov nyob rau hauv cov xwm txheej hnyav ntawm kev kub ceev dov uas yog nrog los ntawm kev kub ntxhov hauv kev ua haujlwm.

Guaranteed nta ntawm forged steel ua hauj lwm yob rau txias dov

High thiab uniform hardness tom qab hardening (nyob rau hauv 1-2 HSD tshaj lub chim)

Txheej txheej qhov tob tshaj lub vojvoog (20-40 mm)

High thermal qaug zog tiv thaiv thaum lub sij hawm zuag qhia tag nrho thiab lub zos tshav kub-up, nce tshav kub kuj (siab hardness yog khaws cia rau ib ntev lub sij hawm nyob rau hauv khov kho-lub xeev thermal tej yam kev mob ntawm yob);

Resistance rau nto defects, tawg, lamination, scabbing, spalling, tearing, thiab lwm yam.

High nto zoo tom qab kev kho cua sov thiab machining

Txaus siab rau kev faib tawm thiab tus nqi tsawg kawg ntawm qhov seem seem tom qab hardening thiab machining

Tsis muaj metallurgical defects thiab impurities

Tsis muaj flakes, coarse carbide pawg, carbide network, loj-hom acicular martensite thiab lwm yam macro- thiab microstructural defects

Yog tsis muaj machining defects

Specification

| Yam khoom | MC3 forged ua hauj lwm rau cov menyuam steel dov zeb |

| Tshuab tes | Rauv yob yog tsim los ntawm statically cam khwb cia trunions (kawg) welded mus rau ib tug centrifugally cam khwb cia yob lub cev nrog peb tshwj xeeb locking mechanism. |

| Kub kub | tuaj yeem ua tau nyob rau hauv high temperture |

| Qhov zoo | Peb cov yob qhuav yog suav nrog statically cam khwb cia trunions (kawg) welded mus rau lub centrifugally cam khwb cia yob lub cev siv nyob rau hauv lub qhov cub |

| peb cov yob qhuav yuav muab ntau cov roj txuag los ntawm kev txo cov cua sov hauv qhov cub |

Qhov zoo:

Ntau tshaj 30 xyoo ntawm kev paub dhau los thiab kev ua haujlwm R&D tas li ua rau peb muaj kev tsim qauv zoo dua thiab cov lus qhia engineering.

Siv tsuas yog cov khoom siv tshiab tshiab xws li npib tsib xee phaj, chrome hlau, cobalt, ferrotungsten kom lav lub cev khoom thiab nce kev pab cuam lub neej ntawm peb cov castings.

Muaj kev tsim khoom hauv tsev thiab tshuaj xyuas qhov chaw kom lav qhov zoo tshaj plaws.

Cov neeg ua haujlwm paub txog kev tsim khoom, machining thiab vuam lav zoo heev thiab xa khoom sai

DESCIPTION of Work Rolls lossis Backup Roller:

1) Khoom siv: Alloy Steel, Alloy Hlau, Cov Hlau Hlau uas yog 9Cr3Mo, 70NiMoV thiab lwm yam.

2) Txuj: GB, AISI, SAE, ASTM / ASME, EU, AS / NZS thiab lwm yam

3) Loj: Raws li cov neeg siv khoom kos duab lossis tsim kev xav tau

4) Hardness: raws li tus qauv tsim

5) Chemical Composition thiab txhua yam khoom: raws li tau teev tseg.

Ntim thiab khaws cia

Cov txheej txheem ntim thiab khaws cia yog nyob ntawm cov ntawv cog lus thiab ntawm thaj chaw huab cua uas cov yob yuav raug muab, nrog rau kev thauj mus los thiab kev cia khoom.

Cov khoom npaj xa tuaj yog them nrog cov txheej txheem preservative - ob peb txheej ntawm primer thiab enamel.

Lub caj dab yob yog qhwv rau hauv daim ntawv anticorrosive nrog polyethylene txheej thiab rau hauv ntawv tsis muaj dej.

Kev khaws cia thiab kev pabcuam

Cov yob yuav tsum tau muab tso rau ntawm qhov chaw tsis muaj cua sov, ntawm cov txee tshwj xeeb, so ntawm lawv lub caj dab.

Kev laus los yog lub caij nyoog qis tempering yog pom zoo pom zoo thaum lub sijhawm ua haujlwm yob lub neej.

Peb lub tuam txhab tshwj xeeb steel tuaj yeem ua ntau yam kev ua haujlwm rolls machining thiab fabrication xws li ntau qhov sib txawv thiab cov txheej txheem raws li tus neeg siv khoom kos duab qhia lossis qhov yuav tsum tau ua.thov koj xav tias dawb ua cov lus nug raws li.