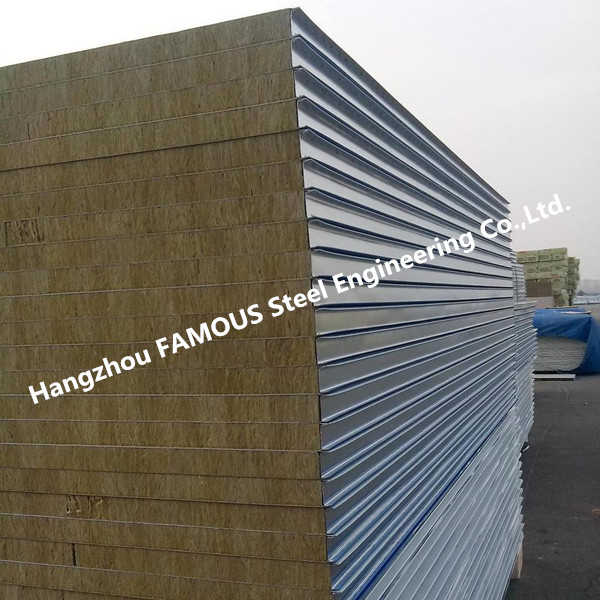

Corrugated Gi Steel Cold Room Panel - Structural Steel Frames Fabrication – FAMOUS

Corrugated Gi Steel Cold Room Panel - Structural Steel Frames Fabrication – FAMOUS Detail:

Petrochemical Pipeline Structural Steel Frames Fabrication for Chemical Industry Equipment

We are:

China’s Top Grade Manufacturer for Steel Structure Manufacturing

A-level for Professional Project Design of Steel Structures

National Grade Ⅰ Specialty Contractor for Steel Structures

Standing director of China’s Construction and Metal Structure Association

Member of China’s Steel Structure Association and Shanghai Metal Structure Industry Association

Deputy Chairman of Zhejiang Steel Structure Industry Association

TECHNICAL PARAMETERS

Besides various prefab steel buildings, we can also do standard or nonstandard Petrochemical Pipeline Structural Steel Frames Fabrication according to client’s sample or drawings:

Special shape structures(super-wide steel plate, etc.);

Industrial steel frames(cement framing, belt conveyor and other supporting frames, etc.);

Platforms(sea drilling platform, viewing platform, etc.);

Car racks;

Steel gallery;

Steel tower;

Steel working tables for workshop;

Chutes;

Reclaimer and decker parts etc.

Elevator shaft steel structure;

Steel staircase;

ETC…

* Products such as Car racks, Steel working tables for workshops, etc., we can provide you with our sample firstly!

PRODUCT SHOW

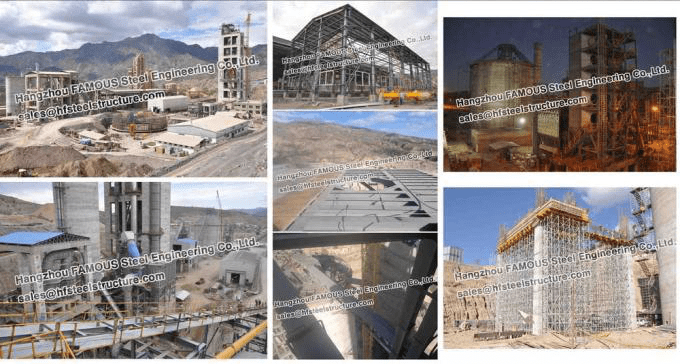

Bolivia Cement Plant

Supporting frames, belt conveyor, workshops, steel staircase, etc.

Steel consumption: 3,655.72 tons in the first phase, 7,200 tons in the second phase

In this project, also includes some special-shaped members fabrication:

| Item Name | Structural steel member fabrication - Industrial steel frames |

| Main Steel | Steel structure–Q345/Q235, special high tension plate, etc. can be customized according to customer’s requirements. |

| Surface | Painted or Hot Dip Galvanized, or according to customer’s requirements. |

| Connection method | welding connection or bolt connection, etc. |

| Column and Beam | Welded H section, Hot Rolled Section Steel, grid column, pipe&tube column,etc. |

| Service | Design, Detailing, Fabrication and Installation (Standard: America Standard, Australia Standard, England Standard, China Standard, etc. Design and Detailing software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, 3D3S, Tarch, Tekla Structures(Xsteel), etc.We also can process/fabricate according to client’s sample or drawings.) |

| Making quotation according to customer’s drawing or as per customer’s dimension and requirement; Offering a free preliminary design drawing(formal complete design need to be paid [high-quality, low-cost] ). |

|

| Packing | We possess the unique most professional and best packaging in China presently – framing package, which perfectly protects the structural steel members from any impact damage during the transport. Or according to customer’s requirement. |

| Load into 40/20GP, 40HQ, 40OT or Bulk carrier |

In FASECBUILDINGS, we take pride in our flexibility and diversification in both services and products, from prototype to production, FASECBUILDINGS is equipped to deliver the structural steel fabrication that your application demands.

Structural fabrication is the use of metal fabrication procedures to produce components for use in a range of applications and industries.

We at FASECBUILDINGS use structural members such as I-beam, angle, channel, flat bar, square, rectangular, and round tubing to fabricate:

- skids

- bottle racks

- platforms

- stairs

- structural supports

- transport equipment

- Chassis

- 8. and a countless variety of other applications, like Hopper, Bins, Silos, Tanks, Cans, Pipeline, custom steel plate etc.

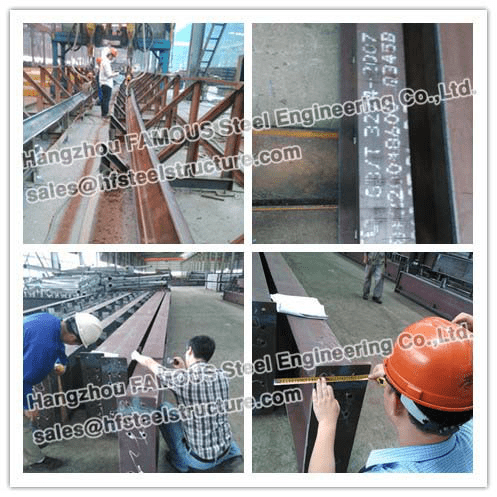

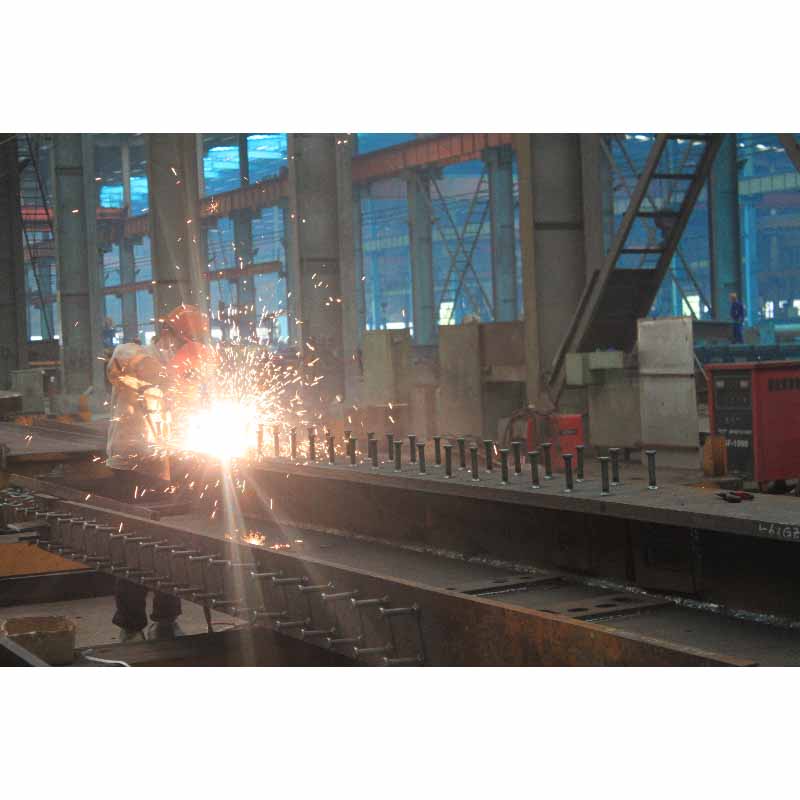

PRODUCTION LINES

Our group introduced from abroad the world-class professional production lines of steel structure, has the most advanced automatic H-beam production lines, pipe truss, box beam production lines, CNC hydraulic punching after-cutting C and Z types steel production lines, wall & roof panels, metal sandwich panel production line, etc., can complete all kinds of light steel, heavy steel, high-rise multi-spatial structure steel products processing tasks with high quality and efficiently.

BOXBEAM PRODUCTION LINE

Box Assembling Machine Intersection Line Cutter Molding Machine

Dual-arc Double Wire Welder Electroslag Welder Face Miller

PIPING TRUSS INTERSECTING PRODUCTION LINE

H-BEAM STEEL PRODUCTION LINE

Tridimensional Drill Machine CNC Sawing Machine CNC Spot Facer

QUALITY INSPECTION BY BV, SGS, SKM, ETC.

Systematic Quality Process and Progress Control documentation: our fabrication process has been controlled by series of documentation and quality testing which are monitored and certificated by BV, SGS, SKM, JACOBES etc world-famous third party inspection organization.

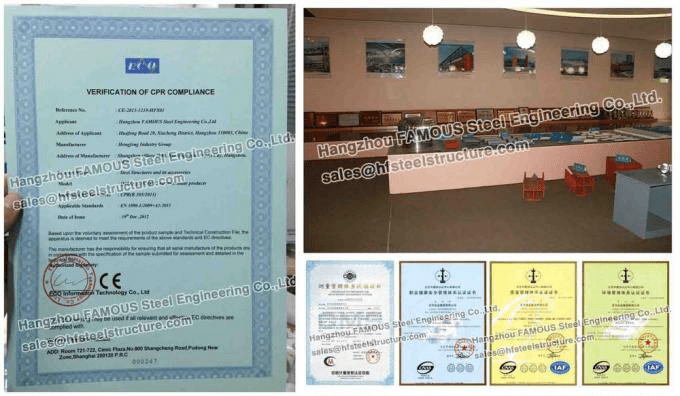

CERTIFICATIONS

We have CE Certificate, AWS Certificate, ISO9001 Quality Control Certificate, ISO14001 Environment-friendly Certificate etc systematic certificates to ensure our whole production progress controllable.

We also have systematic Quality Process and Progress Control documentation: Our fabrication process have been controlled by series of documentation and quality testing which are monitored and certificated by BV, SGS, SKM, JACOBES etc world-famous third party inspection organization.

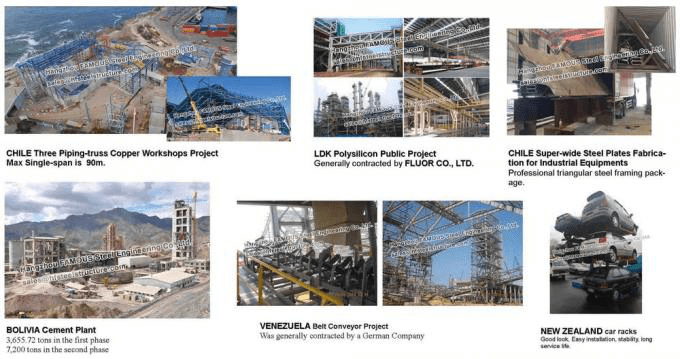

SOME OF OUR STRUCTURAL STEEL FRAME FABRICATION PROJECTS

CHILE Three Piping-truss Copper Workshops Project:

Max Single-span is 90m.

LDK Polysilicon Public Project:

Was generally contracted by FLUOR CO., LTD., the total steel consumption volume for Phase I project reached over 30,000 tons and this program was in a high-rise steel structure of 4-7 floors.

CHILE Super-wide Steel Plates Fabrication for Industrial Equipments:

Professional triangular steel framing package.

VENEZUELA Belt Conveyor Project:

Was generally contracted by a German Company.

BOLIVIA Cement Plant:

Steel consumption: 3,655.72 tons in the first phase, 7,200 tons in the second phase.

NEW ZEALAND car racks:

Good look, Easy installation, stability, long service life.

CUSTOMERS’ VISITS

Welcome your visit!

IF YOU NEED A QUOTATION, PLEASEPROVIDE US WITH THE FOLLOWING BASIC INFORMATIONS:

1. Send us your sample or drawings.

2. If you don’t have, we can design for you.

Product detail pictures:

Related Product Guide:

Rigby High School 2nd Trimester Honor Roll | Local Scenes | Aluminum Sandwich Panel

Velocity Restorations Ford Bronco SEMA restomod driving review | Quick Lifting Doors

Persisting in "High quality, Prompt Delivery, Aggressive Price", we have established long-term cooperation with clientele from both equally overseas and domestically and get new and old clients' higher comments for Corrugated Gi Steel Cold Room Panel - Structural Steel Frames Fabrication – FAMOUS , The product will supply to all over the world, such as: Nicaragua, Sweden, Japan, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

We have been looking for a professional and responsible supplier, and now we find it.