Roof Wall Floor System

-

Fiber Cement Board Cladding Partition Flooring ...

-

Sustainable Exterior Wall Materials for Environ...

-

Wooden Grain PVC WPC Fluted Wall Panels For Dec...

-

wood plastic wall panel hot WPC outdoor ceiling...

-

pvc wall panels decorative wall panels hollow c...

-

Wooden Grain PVC WPC Fluted Wall Panels For Dec...

-

T Ceiling Grid For pvc Ceiling Suspension Syste...

-

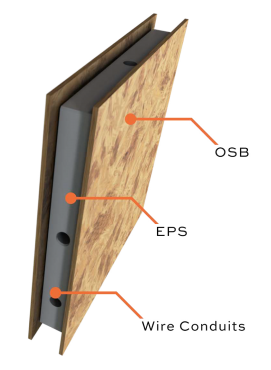

Fireproof osb eps sandwich wall panel and OSB F...

-

Polyurethane PU Edge Rock Wool Sandwich Panel F...

-

Electric smoke exhaust skylight one-line smoke ...

-

Alumtimes Building Facades Modern Audi Sheet 3D...

-

Hot rolled Q345 Carbon Steel Deck Sheets Struct...