Steel Warehouse Buildings

The industrial steel structure warehouse and workshop is a large-scale building designed to provide ample space for storage and manufacturing activities. It is constructed using high-quality steel materials that are durable, strong, and resistant to harsh weather conditions. The warehouse section of the building is typically used for storage of raw materials, finished products, and equipment. The workshop section of the building is designed for manufacturing activities, such as assembly, fabrication, and production.The industrial steel structure warehouse and workshop is a cost-effective solution for businesses that require a large amount of space for storage and manufacturing activities. It is also highly customizable, allowing businesses to design steel buildings to meet their specific needs and requirements.

-

ASTM A36 Q235 steel grating for drain cover dra...

-

MgO SIP Panel/ Structural Insulated Panel/ MgO ...

-

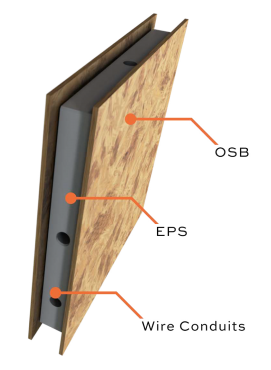

Fireproof osb eps sandwich wall panel and OSB F...

-

Modern design prefab heavy steel structure work...

-

Economic Heavy Steel Structure Workshop And War...

-

Industrial steel warehouse

-

CEMENT PRODUCTION LINE STEEL FRAMES AND CEMENT ...

-

Structural Steel Factory Hall Building Prefabri...