Galvanized Steel Structure

Galvanized steel construction is a popular choice for light poles and traffic signal poles because of its durability and strength. These structures are made of high-quality steel and are coated with a layer of zinc to prevent corrosion and rust. The galvanizing process ensures that the steel structure can withstand harsh weather conditions and last for years without replacement.In addition to strength and durability, the galvanized steel construction is highly customizable. They are designed to meet various specifications and requirements including height, weight, and load capacity. This makes them ideal for everything from small metal storage sheds and galvanized steel-frame buildings to busy highway and intersection signal poles.

-

Hot Dip Galvanized Steel Metal Grating Steel Gr...

-

Q235, Q345 Tubular Traffic lights Signal Steel ...

-

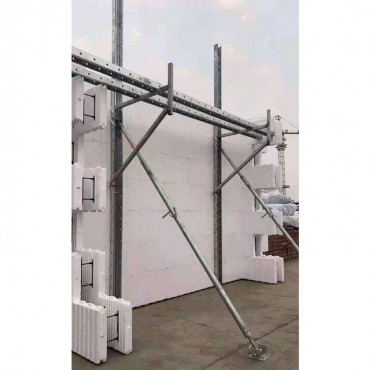

Insulated Concrete Forms EPS BuildBlocks ICF wa...

-

Prefabricated Galvanized 30-50mm Diameter Steel...

-

Electric Lattice Masts Galvanized Steel Pole Po...

-

Cicular Hot Dip Galvanized Steel Pole Monopole ...

-

Tubular Galvanized Steel Pole Monopole for Wind...

-

Galvanized Steel Pole