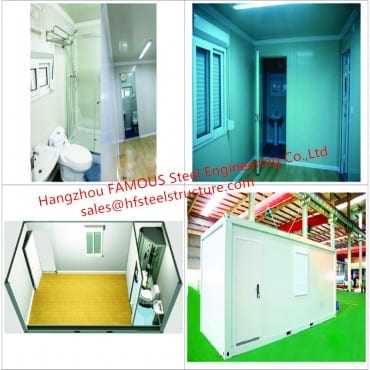

Prefab Container House

-

Prefabricated Container Home Kits Resort prefab...

-

Prefab Customized Container House For Office B...

-

folding house expandable modular home 20ft 40ft...

-

Australia Standard Prefab Expandable Container ...

-

Living shipping container home tiny modular hom...

-

Finely Decorated Modern Luxury Prefab Container...

-

Foldable Living Prefab Container House Modular ...

-

Flat Pack Sandwich Panel Container House Living...

-

Custom Living Container House Dormitory for Pre...

-

Foldable Fireproof Prefab Tiny House On Wheels ...

-

Modern Design Light Gage Steel Framed Foldable ...

-

Salable Mobile Living Tiny Container House With...