Roofing Insulated Panel

-

Wooden Grain PVC WPC Fluted Wall Panels For Dec...

-

Wooden Grain PVC WPC Fluted Wall Panels For Dec...

-

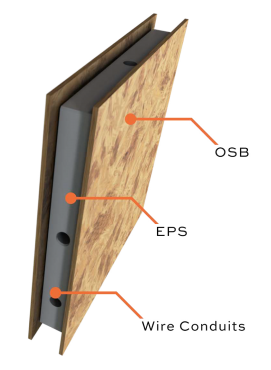

Fireproof osb eps sandwich wall panel and OSB F...

-

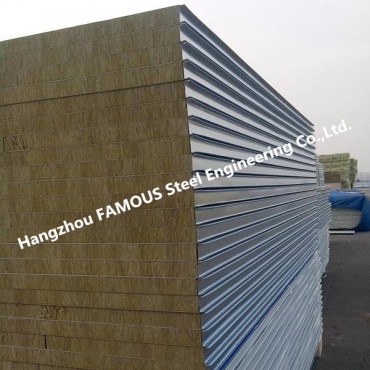

Polyurethane PU Edge Rock Wool Sandwich Panel F...

-

Graphite EPS Sandwich Cement Board Panel Insula...

-

Hot sale color steel pu sandwich wall panel for...

-

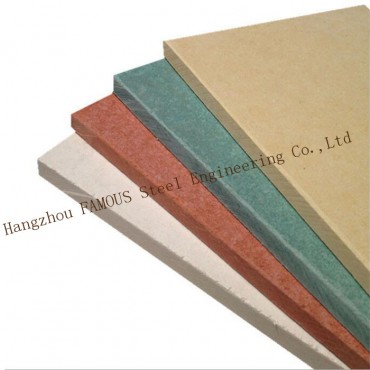

colored interior & exterior wall fiber cem...

-

2.5mm building materials Light Weight Insulated...

-

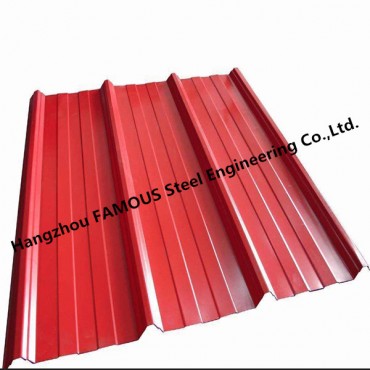

Customized Color Steel Cladding Roofing Sheets ...

-

Mineral Wool Sandwich Panel and Structural Insu...

-

Recycled Usage Fire Resistant Mineral Rock Wool...

-

Galvanized Baseplate Color Steel Cladding Roof ...