Mineral Wool Sandwich Panel and Structural Insulated Rock Wool MGO Sandwich Panel Supplier

Mineral Wool Sandwich Panel and Structural Insulated Rock Wool MGO Sandwich Panel Supplier

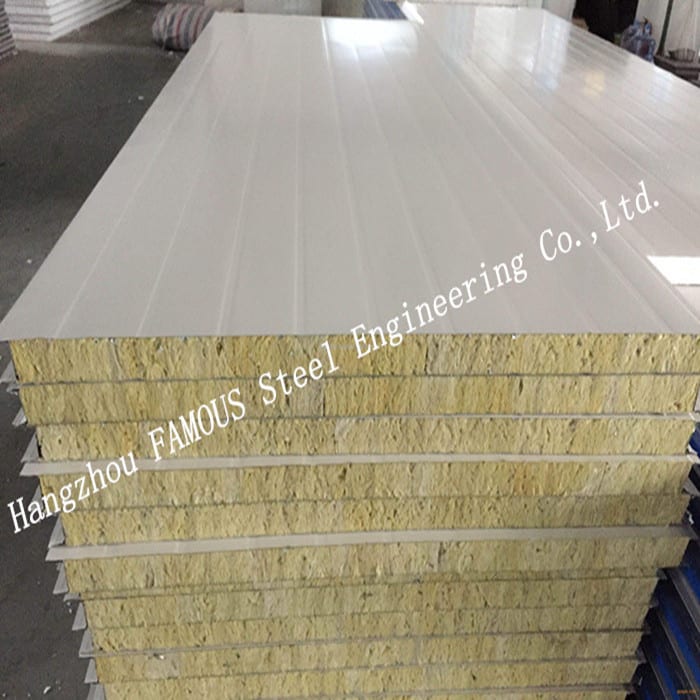

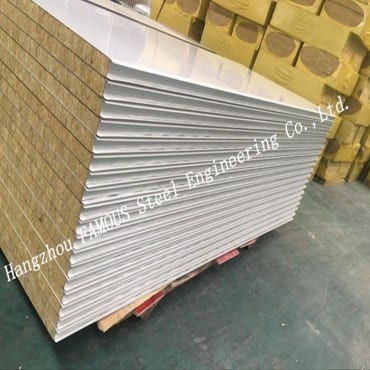

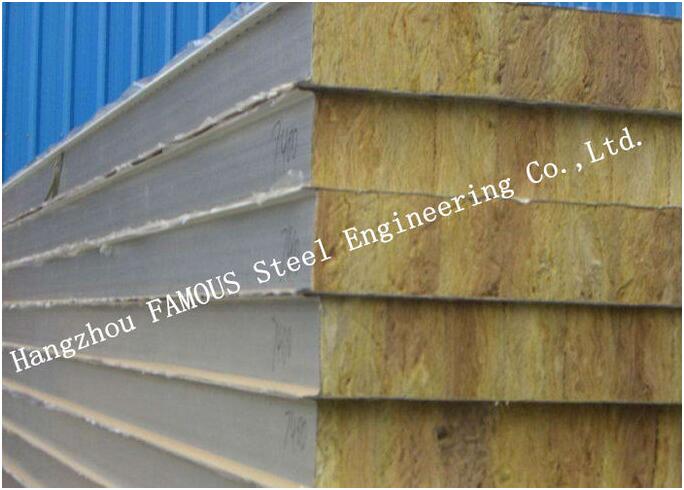

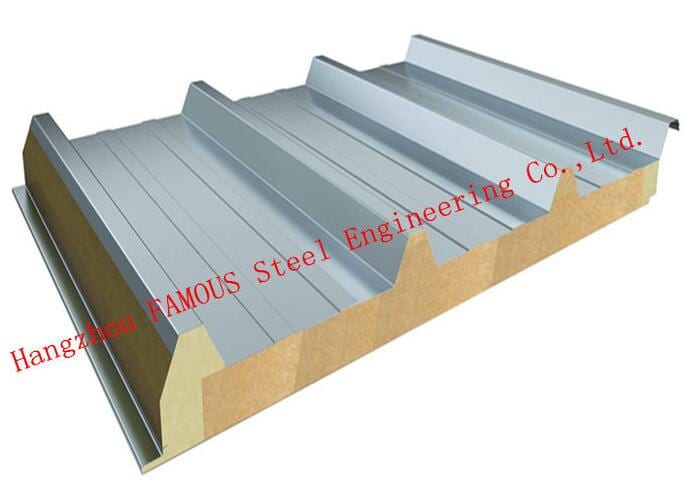

Mineral Wool Sandwich Panel are consist of top and bottom PPGI, Zinc, and Aluminum sheet, with high density basalt wool as core insulation. Due to the excellent performance fire resistance and acoustic insulation, mineral rock wool sandwich panels are commonly adopted for fire-resistance and soundproof buildings.

Specifications:

|

Model |

Mineral Rock Wool sandwich panel |

|

Length |

Customized |

|

Brand |

FASECbuildings |

|

Effective width |

Wall Panel: 950mm 1150mmRoof Panel: 970mm 1050mm |

|

Thickness |

Color steel sheet: 0.3-1.2mm |

|

Materials |

Rock wool core material, Color steel sheet |

|

The Rock Wool density |

80-150kg/m3 |

|

Structure |

Upper and lower layer: Color steel sheet |

|

Steel sheet color |

Ivory white, off white , sea blue, sky blue, lotus green, Grey brick, marble and wooden grain, bright red, etc… |

|

Lifetime |

15~20 years |

|

Character |

Light in weight, heat & sound insulation, fire proof, green and environmental protection |

|

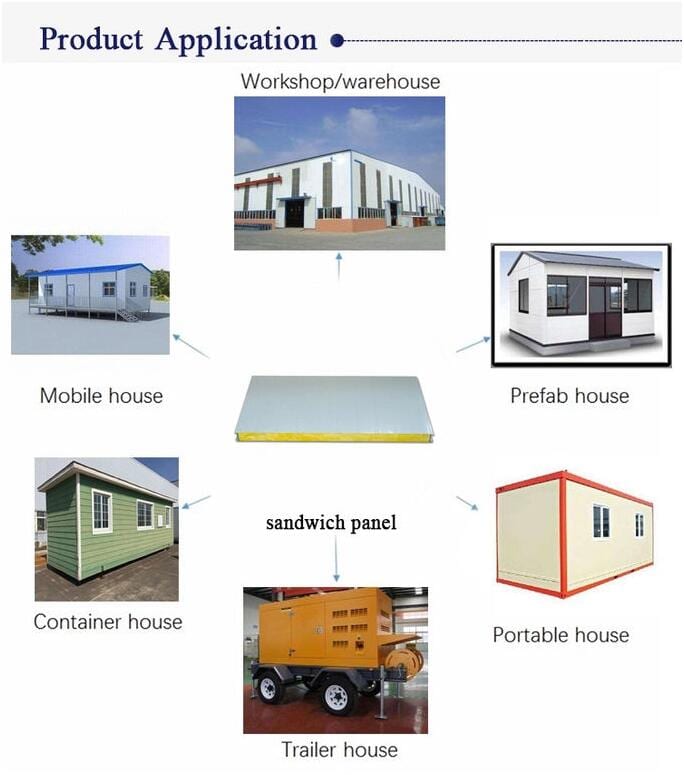

Application |

Gymnasium, warehouse, hospital, supermarket, shelter, commercial and industrial facilities |

Features:

1. Light Self-weight-Installation is convenient and flexible without the large-size lifting devices so that the construction period is limited with the lower comprehensive costs.

2. Heavy Load-bearing Capacity:-It features high strength and high rigidness and is suitable either for the weight-bearing structure or for the protective structure.

3. Good Temp-keeping & Heat Insulation:-With hard polystyrene foams, average thermal conductivity 0.021w/m.k.

4. Fine fireproof-Test by national quality inspection center for fireproof building material, polystyrene sandwich panel index reach grade B2 and grade A of GB8624 respectively.

5. Flexible Application-As the continuous production line is controlled by the computer system, the length of the compound sheets will be decided and selected according to the designing requirement, transportation and installation conditions. It is possible to select the different thickness of the composite panels in accordance with the roof load-bearing and purlin distance.

Advantages:

1. COST SAVING & DURABILITY

As the unique physical structure, rock wool panel is not affected by changes in temperature or humidity. This means the owner can create a pleasant and stable temperature year after year, while saving energy and money for cooling/heating.

2. FIRE SAFETY

Rock Wool Panel Products are rated Non-combustible. Using Rock wool sandwich panel will improve the building’s fireproof performance, protect life and property safety.

3. SOUND INSULATION

Sound is tough to get through rock. Rock wool sandwiched panels are the most effective acoustic insulation used in construction. Installing Rock wool panel provides a real reduction in external noise, whether it’s a workshop, concert hall, air clean room, or residential house.

4. FAST CONSTRUCTION

Rock wool sandwich panels and accessories are produced in full accordance with the building layout drawing, it is fast and flexible to install on the construction site. The construction period can be shortened by more than 40%.

5. LONG LIFE TIME

Rock wool sandwich panel is produced by the automatic production machine at a constant temperature, all the raw materials and process are in strict accordance with the international quality management system, which can guarantee the life time of 25 years.

Installation:

1. You need to ensure that the heat preservation facilities and pipeline surface drying, there is no leakage. rock wool board and rock wool felt have to butt joint closely in order to let the heat loss minimum,

2. It is best to use metal or plastic package on its surface when the rock wool products for outdoor insulation or where vulnerable to mechanical wear, and pay attention to the joint tightness and sealing. If used in cold areas, it must be combined with a layer of moisture proof layer on the surface.

3. The polyurethane rock wool insulation board must be combined with appropriate outer sheath when the temperature is greater than 200 degrees Celsius, and it won’t make the product thickness and density of change.

4. It must be combined with the heat preservation nail, and to guard against when used in large diameter or wall rock wool insulation products equipment and the temperature is greater than 200 ℃.

Applications:

SECTIONAL VIEW OF THE PANELS

TYPE OF SURFACE SHAPE & COLOR:

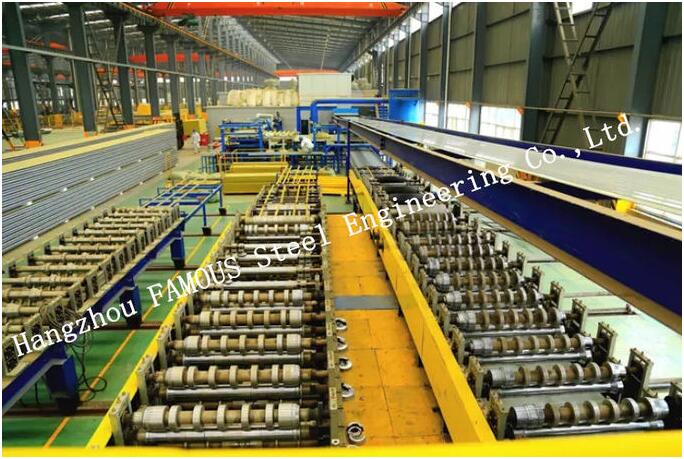

Production Process

For more details, please feel free to send us your enquiry and communicate more specifications. Thanks.