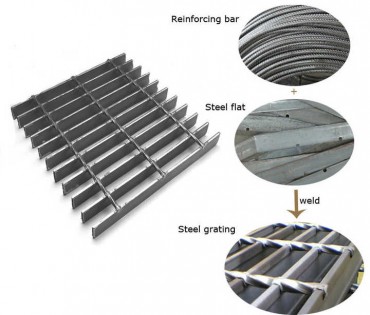

Hot Dip Galvanized Steel Metal Grating Steel Grating Mesh Product

Specification

| Bearing bar( width x thickness) | 25×3, 25×4, 25×5, 30×3, 30×4, 30×5, 32×5, 40×5, 50×5, 65×5, 75×6, 75×10 etcI Bar: 25x5x3, 30x5x3, 32x5x3, 40x5x3 etc |

| earing bar pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3, 32.5, 34.3, 35, 38.1, 40, 41.25, 60 etc |

| Twisted cross bar pitch | 38.1, 50, 60, 76, 80, 100, 101.6, 120mm |

| Surface treatment | black annealed wire, hot dipped galvanized, powered coated, painting etc |

| Greating style | Plain, Smooth, Serrated, teeth, I bar |

| Remarks: other size also can be customized according to customer’s request | |

Overview

Product Description

Material :Mild steel & Low carbon steel, etc.

Surface treatment: hot-dipped galvanized, electric galvanized.

1)Bearing bar shapes: plain or serrated or I bar type.

2)Bearing Bar Pitch (center to center): 30, 40, 60mm are recommended,but we can also do it under customer’s request.

3)Bearing Bar (Load Bar) Specifications (mm):The specification(thickness of bearing bar)of plain type and serrated type is 20 x 3 to 100 x 10;

4)Cross bar pitch(mm) :38, 40, 50, 60, 76, 80, 100, 110, 120 etc.

Steel grating is a type of rigid grid-like structure made from steel bars or sheets. It consists of parallel, flat steel bars or load-bearing strips that are interconnected with perpendicular bars or crossbars. The resulting pattern creates a series of open spaces or gaps, typically in a square or rectangular grid pattern.

The purpose of steel grating is to provide a durable and versatile surface for various applications. Here are some common uses and purposes of steel grating:

Flooring and Walkways: Steel grating is often used as flooring or walkway material in industrial facilities, commercial buildings, and public spaces. Its open design allows for the passage of air, light, and liquids while providing a slip-resistant surface for pedestrians.

Drainage and Ventilation: The gaps in steel grating allow water, debris, and other substances to pass through, making it suitable for drainage applications. It is commonly used as trench covers, drain covers, and platform gratings to facilitate proper water drainage and ventilation in areas prone to moisture accumulation.

Industrial Platforms and Catwalks: Steel grating provides a sturdy and stable platform for workers in industrial environments such as factories, power plants, and refineries. It can be used to create elevated platforms, catwalks, and mezzanine floors that allow access to machinery, equipment, and maintenance areas.

Safety and Security: The open design of steel grating offers better visibility and reduces the accumulation of hazardous materials such as oil, grease, or snow. It is commonly used in areas where safety and security are crucial, such as airports, railway stations, pedestrian bridges, and military installations.

Stair Treads and Ramps: Steel grating can be fabricated to create stair treads and ramps, providing a non-slip surface for safe vertical and inclined access. It is often used in industrial settings, outdoor structures, and public buildings where stairs and ramps require enhanced grip and durability.

Shelving and Storage: Steel grating can be used as a material for shelving or storage racks in warehouses, distribution centers, and retail stores. Its open design allows for better visibility, airflow, and drainage, making it suitable for storing items that may require ventilation or spillage management.

Overall, steel grating is valued for its strength, durability, corrosion resistance, and versatility. It finds applications in a wide range of industries and sectors due to its ability to provide a robust and functional surface while allowing for the passage of air, light, and fluids.