Steel Coil Structural Steel Fabrication - High Wear Resistance Working Rolls For Finishing Machines Anti Rust Alloy Steel Roller With ASTM Standard – FAMOUS

Steel Coil Structural Steel Fabrication - High Wear Resistance Working Rolls For Finishing Machines Anti Rust Alloy Steel Roller With ASTM Standard – FAMOUS Detail:

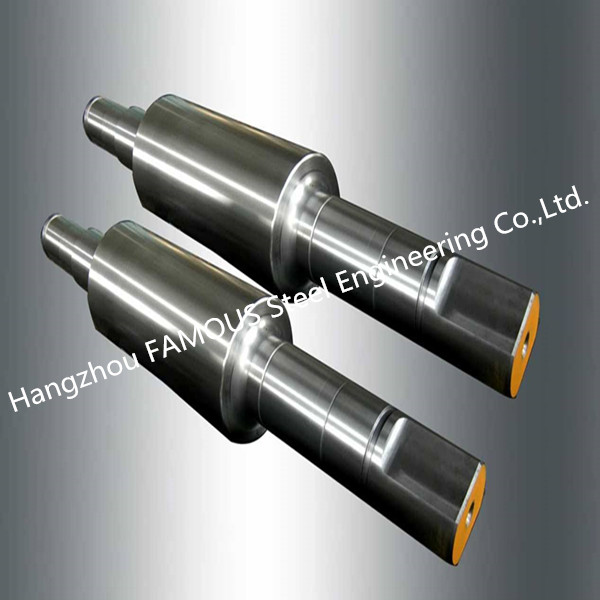

High Wear Resistance Working Rolls For Finishing Machines Anti Rust Alloy Steel Roller With ASTM Standard

High speed steel mill rolls, produced by horizontal Centrifugal casting process, are all compound rolls with high speed steel as the work layer and nodular iron as the core. The material of rolls contains plenty of alloyed elements such as Mo, V, W, Cr etc. The high hardened eutectic carbides & second carbides, such as MC, M2C, M6C evenly distributed in tempered martensitic matrix, make the wear and thermal cracking resistance very excellent. Besides, the resistance to surface roughing is also good. In condition of hot rolling, the contact points between steel strip and the work rolls can form a thin adherent oxide film on the roll surface, which plays a good role in the wear features and the quality of the strip surface. FAMOUS rolls are mainly used as the work rolls in the hot strip mills and the finishing stands of bar mills; rings of the universal section mills and finishing stands of the high speed bar mills.

Usually, we make this type of roll by static cast and centrifugal cast. We recommend using centrifugal cast rolls for better performance when the groove in the roll body is not too deep. With more alloy added in, we can get a microstructure consisting of spheroidal graphite, pearlite and primary carbide type M3C up to 30%. Meanwhile, the core of the roll still keeps very strong with a great amount of spheroidal graphite in the matrix of ferrite. When the groove in the roll body is very deep, we recommend using rolls static cast with groove to achieve a low hardness drop between the body surface and bottom of the groove.

Specification:

| Production Name: | Forged Work Rollers |

| Certification: | CE,BV,TUV,SGS,ISO9000 |

| Technology: | forging,open die forging,free forging,ring forging,stamping,hot,rolling |

| Equipment: | CNC Machining Centres |

| Material: | Carbon steel,Alloy steel,stainless steel |

| Surface treatment: | Heat Treatment,oxide coating,plating,finishing,painting,galvanized |

| Model Number: | Custom According to Drawings |

| Application: | Engineering Construction Machinery |

| Chrome thickness: | 25~30micron |

| Length: | 1001mm~10000mm |

| Weight: | 11kg-3200kg |

| Tolerance: | 0.01mm |

| Roughness: | Ra 0.20micron (max) |

| Packing: | Wood box for free fumigate or according to customers’ requirements |

| Shipment | Sea shipment or customized requirements,etc |

Production process :

Characters:

1. Process: Forged + Machining + Heat Treatment

2. Heat treatment: Normalized / Annealed / Quenched / tempered

3. Delivery condition: Hot forged +Rough machined

4. Inspection Equipments: Metallurgical analysis, Tensile strength tester, Hardness tester, Altimeter, Scale Micrometer, pressure tester, etc.

5. Material: carbon steel ,stainless steel or alloy steel

Slabs are the feed material for hot strip mills or plate mills and blooms are rolled to billets in a billet mill or large sections in a structural mill. The output from a strip mill is coiled and, subsequently, used as the feed for a cold rolling mill or used directly by fabricators. Billets, for re-rolling, are subsequently rolled in either a merchant, bar or rod mill. Merchant or bar mills produce a variety of shaped products such as angles, channels, beams, rounds (long or coiled) and hexagons.

Application:

The spheroidal graphite pearlitic iron rolls are widely used in the roughing stands and intermediate stands of various rolling mills. Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Casting Machinery,etc..

Specification:

| Name | High Speed Steel Mill Rolls |

| Material | 42CrMo, 42CrMo4, 34CrNiMo6 |

| Production ability | 0.75MW-3MW |

| Main production process | Forged+ heat treatment+ rough machining+finish machining |

| Standards | ASTM, ASME, DIN, JIS, ISO, BS, API, EN |

| Delivery Status | N + T (Normalizing + Tempering), with finish machining |

| Production capacity | 1. Open die forging: Max OD: 3800mm; Max weight: 35t; Max height: 2500mm. 2. Ring rolling: OD: 600mm~3800mm; Min ID: 500mm; Max weight: 4t; Max height: 500mm. |

Characters:

1) Material: Alloy Steel, Alloy Iron, Ductile Iron namely 9Cr3Mo, 70NiMoV etc.

2) Standard: GB, AISI, SAE, ASTM/ASME, EU, AS/NZS etc

3) Size: customized as orders

4) Hardness: based on client’s requirements

5) Chemical Composition and mechanical property: as specified.

Certification: ISO 9001: 2008, PED Certificate, TUV Rheinland, Bureau Veritas (BV), Lloyd Register (LR), ABS, RINA Germanischer Lloyd (GL), Korean Register of Shipping (KR), Det Norske Veritas (DNV), Nippon Kaiji Kyokai (NK) etc can be obtained per project needs;

Our special steel company can do various customized work rolls machining and fabrication ranging in different sizes and processes as per client’s drawing shown or the requirements. please feel free to make any enquiries accordingly.

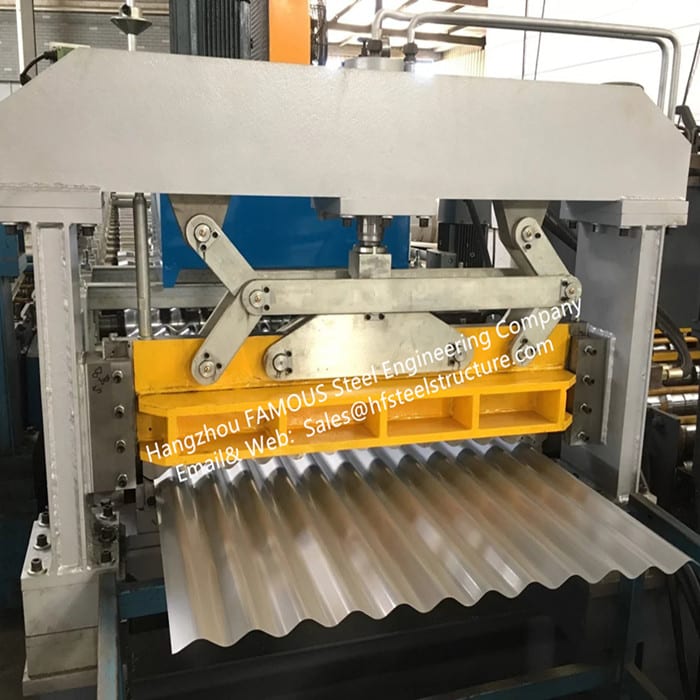

Product detail pictures:

Related Product Guide:

Floor Sandwich Panel Market Analysis by Key Players, Size, Competitive Analysis, Global and Regional Forecast | Quick Lifting Doors

How Masood Azhar was finally blacklisted by UNSC | masood azhar | global terrorist | Aluminum Sandwich Panel

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for Steel Coil Structural Steel Fabrication - High Wear Resistance Working Rolls For Finishing Machines Anti Rust Alloy Steel Roller With ASTM Standard – FAMOUS , The product will supply to all over the world, such as: luzern, Ghana, Yemen, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.