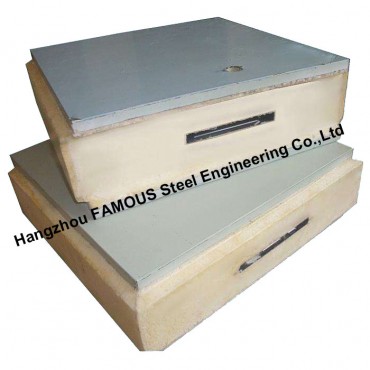

Manufacturer Insulated Polyurethane Board Color Stone Sandwich Panel Wall For Cold Room

Manufacturer Insulated Polyurethane Board Color Stone Sandwich Panel Wall For Cold Room

Application

PU Sandwich panel (Polyurethane sandwiched panel )is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. It is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, which features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

Features

High strength, wear resistant, oil resistant, shock absorption, heat preservation effect is good.

| Type | Polyurethane(pu)Sandwich Panels |

| Panel Material | Painted steel sheet,stainless steel sheet,or other. |

| Place of Origin | China |

| Density | 40-42kg/m3 |

| Length | Customize |

| Effective Width | 1000mm |

| Core thickness | 50mm,75mm,100mm,150mm,200mm |

| Features | soundproof, fireproof, waterproof |

| Certificates | CE, ISO14001, ISO9001, |

| Color | White, Grey, Sliver, Sea Blue, Red, etc. as required |

| Lifetime | 20-30 years |

| Fire proof rate | B1 |

| Usage | Vatious roofs and walls referring to the large size factory Building,storages,exhibition halls,gymnasiums,etc. |

Produce Advantage

1. Heat insulation pu sandwich panel (the abbreviation of Polyurethane is PU sandwich panel) have characteristics of high load intensity, small water-absorptive, and the stability in either low temperature or the high temperature is good, the service life is long, thermal insulation performance is outstanding and so on.

2. Good supporting, heat resistant, sound-insulated, sound absorption, light quality, non-toxic, odorless, green environmental protection.

3. PU freezer sandwich panels can cementation with the steel plates, the cements, the fiberboards, the bricks and many kinds of materials very strongly, in usual situation, it would not fall off and still strengthen its thermal insulation and waterproofing effects.

4. The unique produce foaming craft made the products have exquisite and even abscesses, the Thermal conductivity is low, the size stability is good, is very suitable for both of the low pressure and the high pressure construction.

| Product name | Polyurethane (PU) Sandwich Board | |

| Thickness | upper layer | 0.5-0.8mm |

| core material | 75mm, 100mm, 120mm,150mm | |

| bottom layer | 0.5-0.8mm | |

| Effective Width | standard | 960mm |

| other | can be customized | |

| Length | can be customized, less than 12m | |

| Density | 38-40kg/m3 | |

| Weight | up to model | |

| Color | any (generally white, blue, red, grey,) | |

| Temp tolerance | -120-90℃ | |

| Fire resistance level | A2 (incombustible) | |

| Surface profile | flat,corrugated,big rib, small wave | |

| Compression bearing | ≥0.2Mpa | |

| Material | upper layer | PPGI (prepainted galvanised steel) color steel sheet |

| inner layer | PU foam (injected, not glued) | |

| bottom layer | PPGI (prepainted galvanised steel) color steel sheet | |

| Parts | Eccentric hook used for connection of panel | |

| Film covering for protecting the surface layer | ||

| Heat transfer coefficient | 0.019 W/M*K | |

| Characteristics | heat insulation energy-saving | 100mm width can keep temp at 0℃ (suit for fresh keeping) |

| 150mm width can keep temp at -18℃ (suit for cold storage) | ||

| 200mm width can keep temp at -38℃ (suit for freezing) | ||

| water resistance and sound proof | ||

| weather proofing | ||

| fire retardant level:B | ||

| high strength and bending resistance | ||

| easy quick installation and dismantling,labour cost saving | ||

| light weight compared to traditional stone or plaster panel | ||

| safe and green,good appearance,without formaldehyde | ||

| Lifespan | can reach 15-20 years | |

| Usage | Can be used for wall,roof,floor and partition of cold storage, mobile house, suburban housing, suburban housing,industrial plants, warehouses, supermarkets, hospitals, stadiums, activities room,clean workshop and reconstruction residence, villa, kindergarten, commercial building, remodeling of old structures, heat insulation fire places, airport, etc. | |