Metal Fabrication

Famoussteel's metal fabrication services are second to none. We use the latest technology and equipment to create custom metal products that meet your exact specifications. From design to delivery, our team of experts will work with you every step of the way to ensure your project is a success. Whether you need a single prototype or a large production of prefab steel structures buildings, we have the experience and expertise to get the job done right. Our commitment to quality and customer satisfaction is unmatched, and we pride ourselves on delivering projects on time and within budget.Contact us today to learn more about our metal fabrication services and how we can help bring your project to life.

-

Hot Dip Galvanized Steel Metal Grating Steel Gr...

-

Army Portable Steel Bailey Bridge Painted Or Ho...

-

Fire-proof Door Light Steel Villa Luxury Light...

-

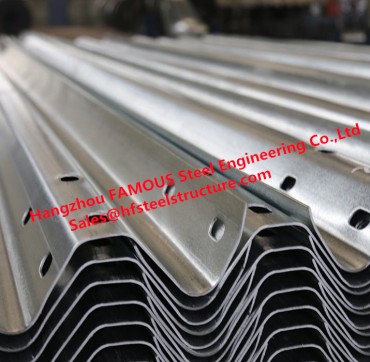

Cost-effective Urban Road Protection W Beam Saf...

-

Concrete Slab Decking Sheet Metal Decking Sheet...

-

Q235, Q345 Tubular Traffic lights Signal Steel ...

-

AS 5100 Design Standard transportation enhancem...

-

Hot rolled Q345 Carbon Steel Deck Sheets Struct...

-

Prefabricated Light Beam Structure Frame China ...

-

2022 Latest Luxury and Modern Prefabricated Lig...

-

Furnished Light Steel Structure Prefabricated L...

-

Australia Standard Customized Light Steel Villa...